Keeping your boat ready to go!

Shortly after we bought our powerboat, (a Duffy 35’ downeast style lobsterboat) I was looking at the plaque on the top of the engine to get the model number off it. I noticed that the plaque included the “continuous horsepower rating” for my engine. Curious, I checked out what that meant and essentially, it’s the rated horsepower for the engine when it is run 24/7 365 days a year. Engines for diesel trucks (often the same engines we use in our boats) are designed to run for up to 200,000 hours before needing to be rebuilt. Commercial diesel trucks are designed for a lifespan of over a million miles. When we bought our boat, the engine had 1300 hours on it and the boat was already close to 20 years old! Most of us are hard pressed to put 200 hours per year on our engines, if we own an auxiliary powered sailboat the hours add up even slower.

"Due Regard” waits in Oxford, MD on the Chesapeake for her next adventure. Photo by: Chris Snow

As you can see, we hardly put any hours on our recreational boat engines and therein lies the problem. Most issues that arise in the recreational marine area come from lack of use rather than overuse. So how to deal with that and have our fun boat ready to go whenever we want to use it? Here are some thoughts for you:

Run mechanical systems regularly:

Whether you can use it or not have your main engine and generator run for at least half an hour every two weeks. One of the biggest issues seen in boats that sit is buildup of debris and corrosion in the cooling system (heat exchangers). Running these engines regularly will ensure that the systems are kept reasonably clean and flushed. Allowing your engine’s cooling system to sit for months without seawater (and cooling water) running through the heat exchanger is a recipe for much larger problems. No matter how you slice it water is corrosive. Allowing it to sit in your cooling system is just not good. If you cannot do this yourself arrange with someone you trust to make this happen. Check your engine and genset manuals for when the cooling systems on these should be serviced. This is usually done by removal of the heat exchangers, intercoolers, etc. and taking to a marine radiator shop for a flush and clean. It should be done on time.

Pay attention to leaks:

Pay attention to leaks. While this may seem obvious, I see many people just assume that a little leak from either seawater into the bilge or from the engine(s) is OK and normal. Leaks do not fix themselves and they are not “normal”. The best way to monitor a leak is by placing a fresh absorbent “zorb” under the suspected area and monitoring. This will help for an oil or hydraulic fluid leak. In the case of a suspected water leak place a blue paper towel under the suspected area. Any leakage will show up quickly and you’ll be able to pin point the source.

In the same vein, I suggest keeping your bilges as dry as possible. Again, this is mostly for monitoring leaks or potential leaks. A dry bilge also keeps your boat smelling better. Find the lowest point in the boat and if there is any water be sure to remove it completely prior to heading out on the water. When you come back and check the bilge and water is present, then you know you have leakage. On many boats, this is usually the stuffing box where the propeller shaft exits the boat. Most newer boats have “dripless” stuffing boxes meaning there should be no water leaking in. A tip for removing water deep down on the bilge. Use a wet/dry “Shopvac” with a piece of PVC pipe on the end to get down into the deep recesses of your bilge.

A clean bilge is a sign of a well cared for boat.

Keeping the bilge clean cuts down on odor and allows you to see any leaks right away. Photo: BoatTest.com

The all-important battery system:

Pay close attention to your boat’s battery system. Without a strong battery system, your boat is literally dead in the water. The basic idea is that the starting batteries for the engine and generator need to be isolated from other potential uses. This ensures that their full power is always available to start the engine and generator (if you have one). Once the engine is started, you can use the engine alternator to charge the rest of the batteries on the boat if needed. These are typically the house batteries (used to run lights, refrigerators, toilets, etc.) and the auxiliary battery for the bow thruster and windlass. Note also that you can use the generator to charge batteries by running it and your 120V powered battery charger.

All boats vary somewhat and you should know how your batteries are isolated from or tied to each other. Note that the biggest current draws on any boat are the bow thruster and the windlass. It is for this reason that you should not operate either of these without the engine running (especially if either are tied to the starting engine battery).

On most boats, it is possible to “tie” the house and starting batteries together in an emergency to start the engine (if the engine start battery is low). You should know how to do this.

I highly suggest that you have a “smart” monitor installed for your house battery banks at least if your boat does not have one already. When running accessories and lights off the house banks these monitors will show you how many amps you are consuming and when charging how many amps are going into the batteries. They will also show you the state of charge as a percentage rather than volts which is much easier to understand.

Victron BMV 12 Smart Battery Monitor

The monitor is showing 14.4 amps of current flowing in to charge the house batteries. This monitor has alarms for high and low voltage and for high temperature (good for lithium ion batteries with sensors fitted). It also can connect to your cell phone via app. Photo by: Chris Snow

Another thing I strongly suggest, if your batteries are older is having them load tested. This is the best way to tell the health of your batteries and should be done by a qualified marine electrician with a proper tester. Replacing large heavy boat batteries is a big job (standard 8D batteries weigh about 180 pounds each), and is expensive. Planning ahead and replacing BEFORE you have an issue is smart. If you are looking at buying a used boat, insist that the batteries be load tested as part of your inspection or survey. This is often not done and can result in a big and expensive surprise to a new owner.

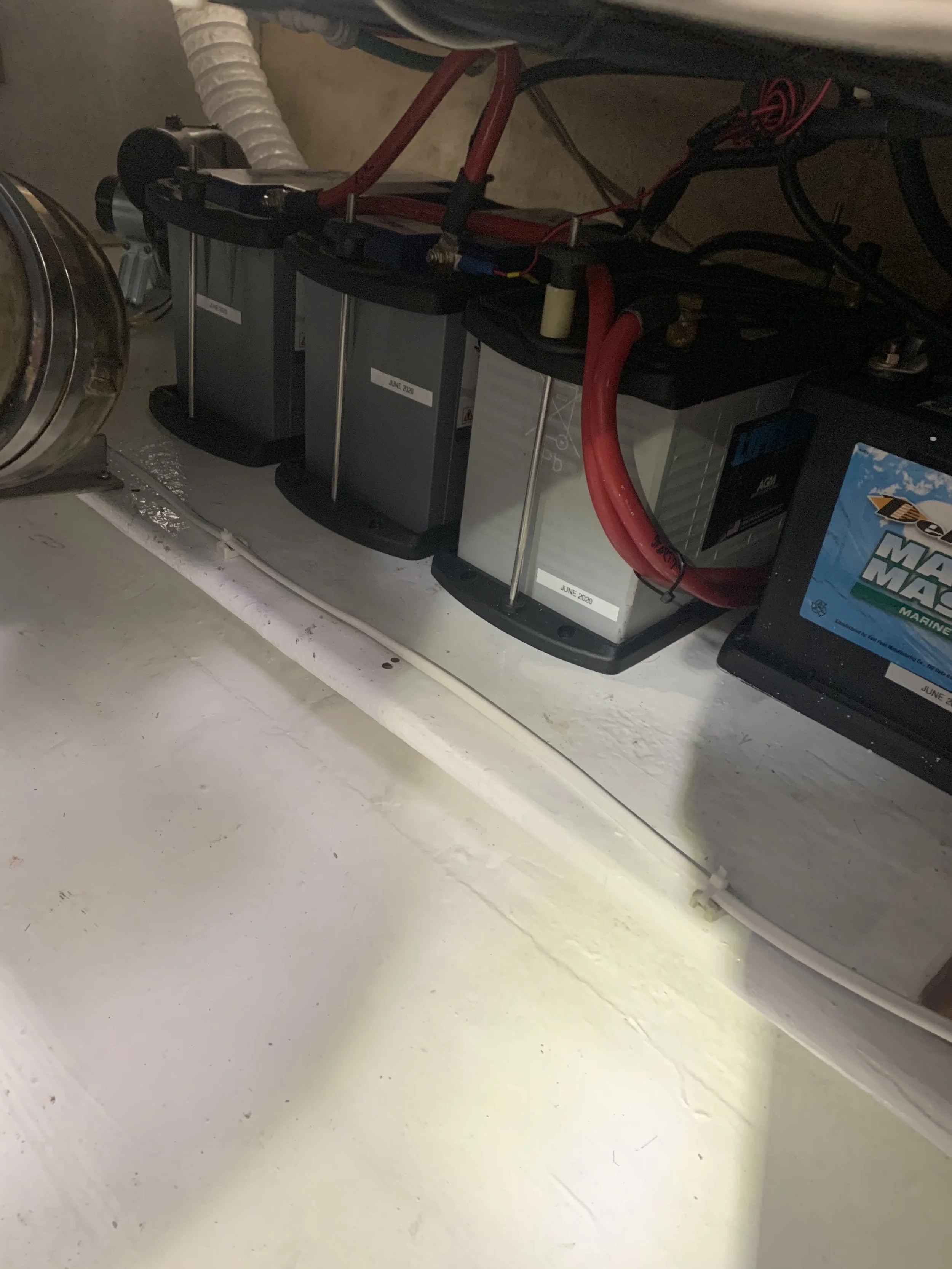

One last thing on batteries is when you replace a bank of batteries be sure to replace the whole bank even if just one battery (or cells in one battery) are bad. While this is surely more expensive it will save hassle down the road by keeping the older, weaker batteries in the bank from parasitically leeching off the stronger newer battery. Always label the month and year directly on the battery when you install new ones.

These batteries are clearly labelled with the date and year they were installed eliminating any confusion in the future.

Typically you should replace all batteries in a bank at the same time. Photo by: Chris Snow

We all own our boats to have fun on them. The last thing any of us want is to come down to the boat and not be able to head out because of some preventable mechanical issue. Hopefully by following what is given here you can avoid that and have some great days on the water.

If you have any questions or I can provide any assistance please reach out.